Increasingly vulnerable assets and interdependent infrastructures mean Planned Preventative Maintenance (PPM) is now just as critical to organisations as resilience.

While resilience solutions proactively guard against the more obvious and large scale disruptive events, PPM guards against the less noticeable (but equally damaging) dangers that so often cumulate to create costly and unexpected problems down the line.

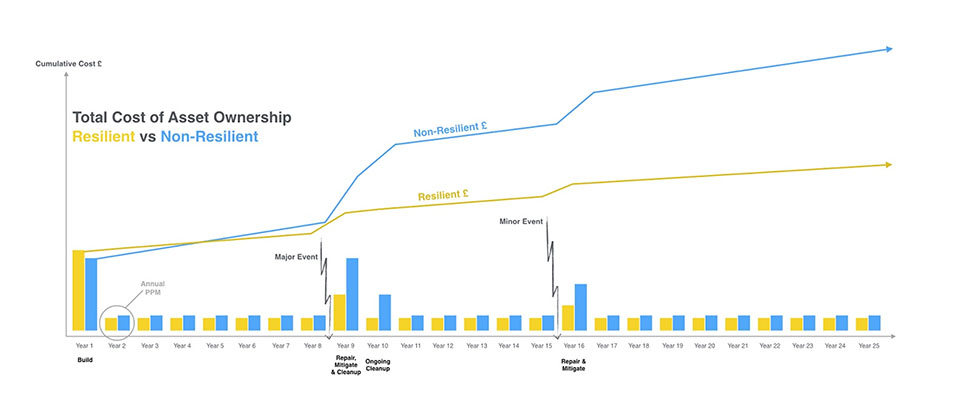

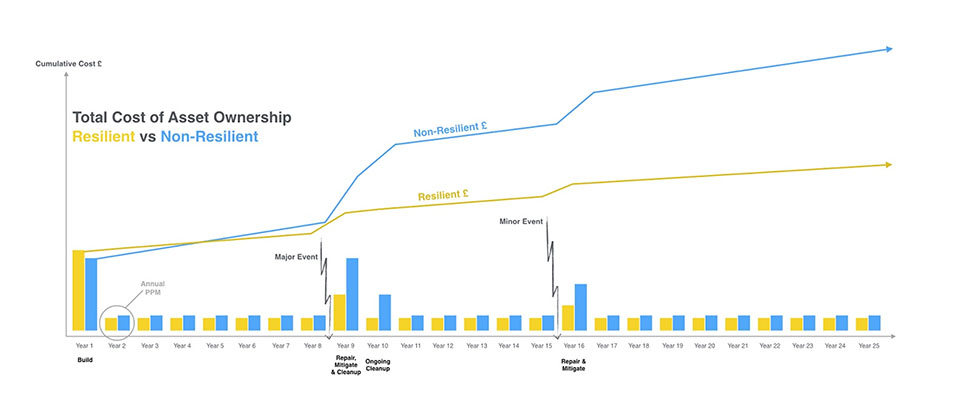

Organisations today are advised to include PPM services to deliver added value where possible. Coupled with asset resilience measures, PPM will quickly offset any front-loaded costs of implementation. This is shown the graph, providing an approximation of the cost difference between two assets over a span of 25 years.

When it comes to protecting your assets, prevention is definitely better than cure, with planned maintenance essential to ensuring profitability, personnel morale and the effective management of time, not to mention minimising the risk of damaging and costly environmental incidents across an entire site, compound, or infrastructure. Adler & Allan’s Planned Preventive Maintenance program includes a comprehensive site assessment by specialist engineers who as part of the PPM assessment will generate a full environmental asset list and provide an overview of equipment status.

Our Planned Preventative Maintenance services are delivered to a wide range of sectors, including Defence, Government agencies, National utilities, Facilities Management, Logistics and Transport companies, covering the following areas;

Oil storage surveys and maintenance – OFTEC compliance:

OFTEC regulations surrounding oil storage are becoming increasingly stringent, with costly repercussions for those who don’t comply. Adler & Allan’s OFTEC accredited auditing ensures oil storage facilities meet current legislation. We also undertake tank inspections to EMMUA 159 Level 2.

Interceptors and site gullies:

Interceptors are often the last line of defence between a controlled oil spill and a major pollution incident, so keeping them in top condition could be crucial in the event of an emergency – the fines resulting from one such emergency will exceed decades of regular Planned Preventive Maintenance.

Fuel compliance testing & polishing:

Fuels are susceptible to natural deterioration, with the replacement of contaminated fuel more expensive than ever. Most poor fuel conditions can be corrected without major expense, if conditions are diagnosed promptly.

PPM of tanks, pipework, heating and the following:

- Petrol Oil & Lubricant (POL) maintenance

- Separator installation and maintenance

- Pumps, gauges, valves and alarms

- Automatic Tank Gauging Systems

- Bulk Meter Servicing

For more information on our wide range of services and solutions, call us on 0800 592 827, view our latest case studies, or contact us.